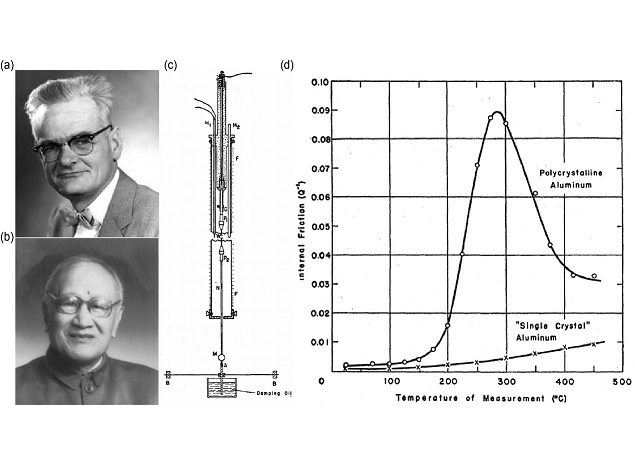

Internal dissipation or internal friction is essential for nearly all solids to dissipate kinetic energy through internal mechanisms. The pioneering analyses by Zener and Kê demonstrated the existence of a single friction peak in the loss modulus spectrum of polycrystalline solids (see Fig. 1), which is attributed to viscous sliding in grain boundaries (GBs) and is confirmed by more experiments on different polycrystalline materials.

However, there are also experimental reports on two internal dissipation peaks related to GB relaxation in ultra-fine grained polycrystalline materials but the existing analyses don’t predict two peaks. Such inconsistency may arise from the standard treatments that model GB as a slippery interface and do not account for the viscous or elastic deformation in the normal direction of GB. As grain size decreases down to nanometers, GB volume fraction becomes important, and treating GBs as zero-thickness interfaces is no longer valid.

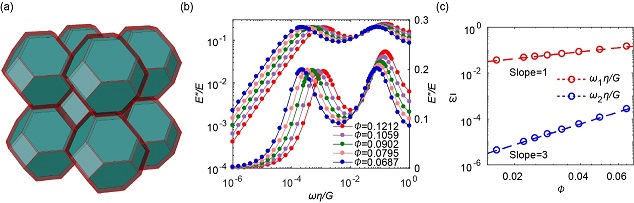

Researchers at the Institute of Mechanics, Chinese Academy of Science developed a computational method to couple elastic deformation, viscous creep and diffusion in grain boundaries and reveal the existence of a second loss modulus peak resulted from viscous deformation in GBs (see Fig. 2). The corresponding two frequencies, when internal dissipation reaches its local maximum, depend on grain size d : the lower frequency one is proportional to d-3 , and the higher frequency one (Kê peak) is proportional to d-1 . The condition when the two peaks emerge is identified. The findings can be applied to granular and porous materials, and complex rheology in geosciences, where internal dissipation is momentous for waves and seismic activities.

The paper is published in the journal Acta Materialia (https://doi.org/10.1016/j.actamat.2020.10.004).This research was supported by the NSFC Basic Science Center for 'Multiscale Problems in Nonlinear Mechanics' (No. 11988102) and (No. 11790291), the Strategic Priority Research Program of the Chinese Academy of Sciences (XDB22020200), and CAS Center for Excellence in Complex System Mechanics. Computation was supported by Beijing PARATERA Tech CO., Ltd

Figure 1. (a) Clarence Melvin Zener. (b)T’ing-Sui Kê. (c) Apparatus for measuring internal friction and dynamic rigidity of wire specimen developed by Kê. (d) Variation of internal friction with temperature in polycrystalline and "single crystal" aluminum adopted from Kê (Phys. Rev. 71 (1947) 533-546).

Figure 2. (a) Representative samples used in this study, with grain interior shown in green and GBs in red. (b) Loss modulus spectra in polycrystalline solids with finite grain boundary thickness and different grain size. (c) Grain boundary volume fraction (grain size) dependency of the dissipative behavior in polycrystalline samples at two particular frequencies