Triboelectric nanogenerators (TENGs), first proposed in 2012, can collect mechanical energy extensively through contact initiation and electrostatic induction. After some years of development, TENGs have shown a wide range of applications in self-powered sensors and mechanical energy harvesting. The contact-separation mode has become one of the most fundamental and common modes of working.

Many works have been made by previous researchers for improving output signal of contact-separation TENGs. For example, for increasing the surface charge density, it is common to microstructure the friction layer surface. For contact-separation TENGs with abundant space, multilayer designs have also been used to increase the area for storing charge. Another recent novel approach is adding a pump to the TENG for overcoming the limitation of the maximum surface charge density of the friction layer. The strategies mentioned above are all aimed at increasing the surface charge. The magnitude of the output signal is related not only to the amount of charge transfer but also to the charge transfer speed.

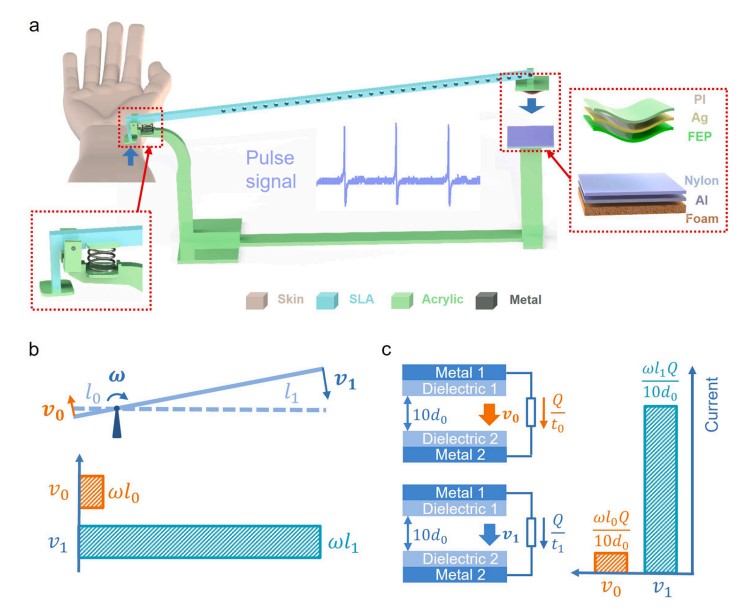

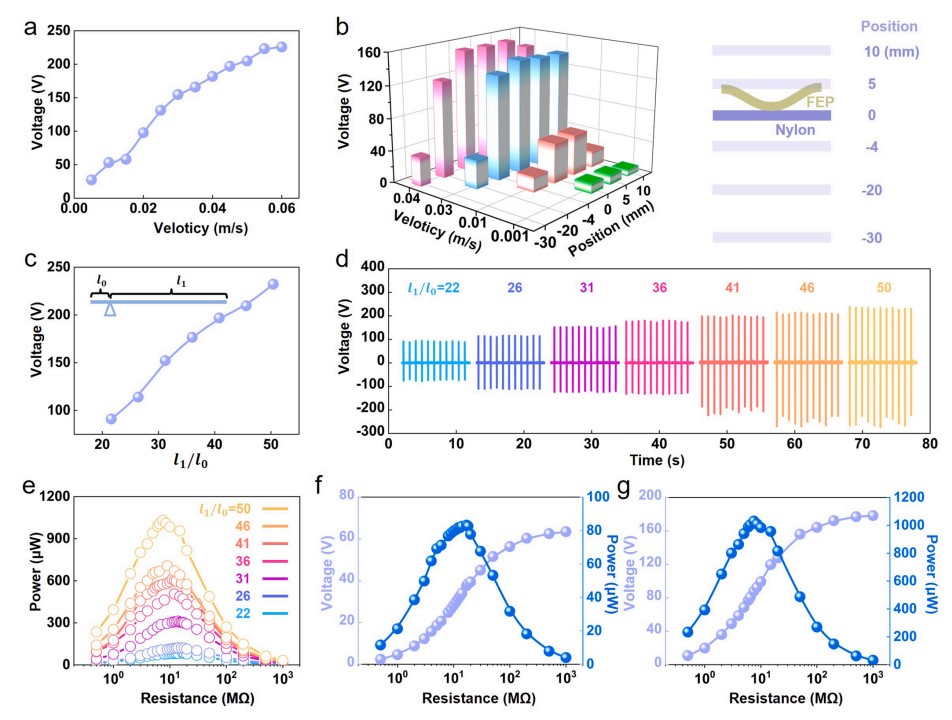

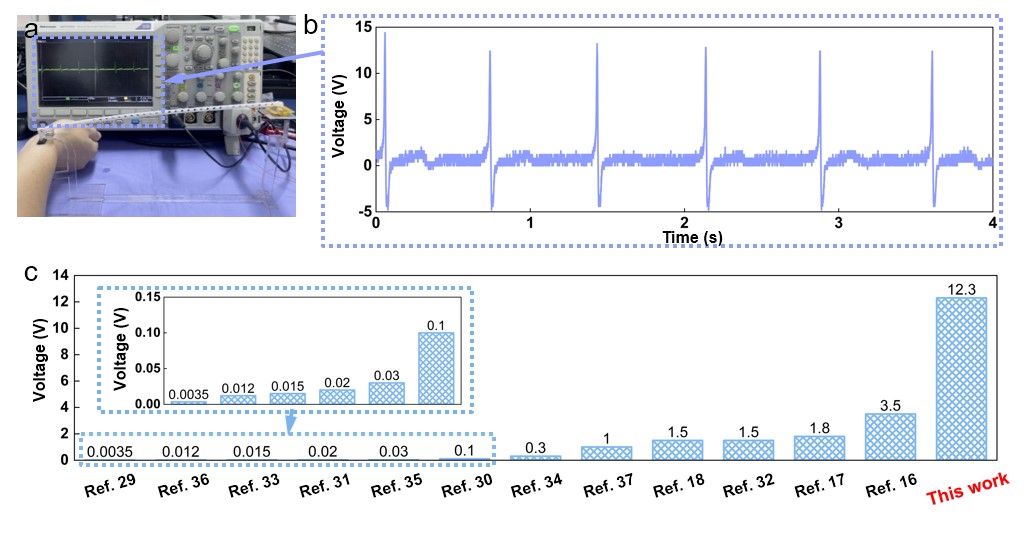

Recently, researchers from the Institute of Mechanics, Chinese Academy of Sciences and Beijing Institute of Nanoenergy and Nanosystems, Chinese Academy of Sciences have proposed a new strategy aimed at increasing the charge transfer speed, provide new paths for improving the output signal, and develop a lever-inspired contact separation TENG (Li-TENG), as shown in Figure 1. By varying the lever ratio to change the contact separation velocity, the signal output can be significantly increased without changing the charge transfer amount. To accommodate the unique rotational motion of the lever, we designed the upper friction layer in the curved shape and investigated the electrical and mechanical properties of the curved-shaped friction layer under different compression strains. When the magnification was increased from 22 to 50 times, the voltage of Li-TENG increased from 91 to 232 V and the maximum power from 83 to 1031 μW (Figure 2). As self-powered pulse sensor, the Li-TENG measured a pulse signal of 12.3 V without surface microstructure treatment, which is much higher than other literature (Figure 3). This work demonstrates a new strategy for improving the signal of contact-separation TENGs, which has great potential for improving the signal of contact-separation TENG-based self-powered sensors and energy harvesting devices.

Related results were published in Nano Energy (https://doi.org/10.1016/j.nanoen.2022.107159).

Figure 1. Model diagram and schematic diagram of Li-TENG. (a) Model diagram of Li-TENG. (b) Schematic diagram of angular velocity. (c) Schematic diagram of TENG current.

Figure 2. Electrical measurements of Li-TENG. Voltage measurement at (a) different speeds and (b) different positions. (c) Voltage signal and (d) voltage waveform at different magnifications. (e) Power diagram at different magnifications. Voltage power diagram at (f) 22x magnification and (g) 50x magnification.

Figure 3. Li-TENG for pulse measurement applications. (a) Physical and (b) signal diagrams of pulse measurement with Li-TENG. (c) Comparison of the pulse signal measured by Li-TENG with other literature.

Contact

MS. zhang

Institute of Mechanics, Chinese Aademy of Siences

Tel : +86-10-82544075

Email: zhanglingfang@imech.ac.cn

Web: http://english.imech.cas.cn/