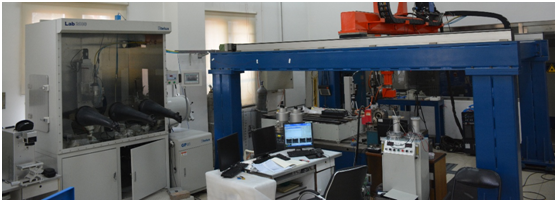

Integrated laser intelligent manufacturing and flexible processing system is a set of equipment systemwith independent intellectual property rights (a number of national inventions and utility model patents). The whole system includes high power solid-state laser machine, high precision five axis robot frame, full value and feedback control system, flexible beam transmission and transformation system, CAx database system and auxiliary system, etc.. The system can not only be used as an experimental platform for the research of the mechanism of laser advanced manufacturing process, but also can meet the industrialization demand of large-scale laser advanced manufacturing. It has a wide application prospect in the fields of machinery, electronics, aviation, medical treatment and so on.

Equipment available

1. Laser system

(1) German semiconductor excitation all solid state laser (DPSSL), wavelength 1.06 micron, laser output 0-1000W (average power), pulse waveform can be arbitrarily set, 0.1mm optical fiber transmission

(2) Germany made HL2006D Nd:YAG continuous laser machine, wavelength 1.06μm, laser output 0-2000W (average power) /0-200 J (single pulse energy), pulse waveform can be arbitrarily set, 0.6mm optical fiber transmission

(3) French made IQL-10 Nd:YAG pulse laser machine, single pulse energy: 0-55J,pulse width: 0.2-25ms, waveform setting: ten stage superposition, average power: 500 W, peak power: 3 kW, pulse number: 0-30000, optical fiber transmission

(4) Domestic made YAG laser machine with maximum output power of 200W. Pulse laser output can be generated by acousto-optic modulator

2. Robot worktable system

4m * 3m frame type robot worktable system: five axis linkage, working range: 2.5 x 1.9 x 1, rotation (A, C axis); repetitive positioning accuracy ±0.01mm. The carrying system can bear 20 tons and has the function of positioning.

3. Testing equipment and other equipment

(1) Adaptive fast positioning measurement system

(2) Coaxial powder feeding system

(3) Optical experiment platform

(4) Wear test machine

(5) Microhardness tester

(6) Laser beam analyzer

4. Virtual experiment platform and numerical control platform

A virtual numerical simulation platform based on numerical simulation and a numerical control platform for autonomous programming based on control theory are established.