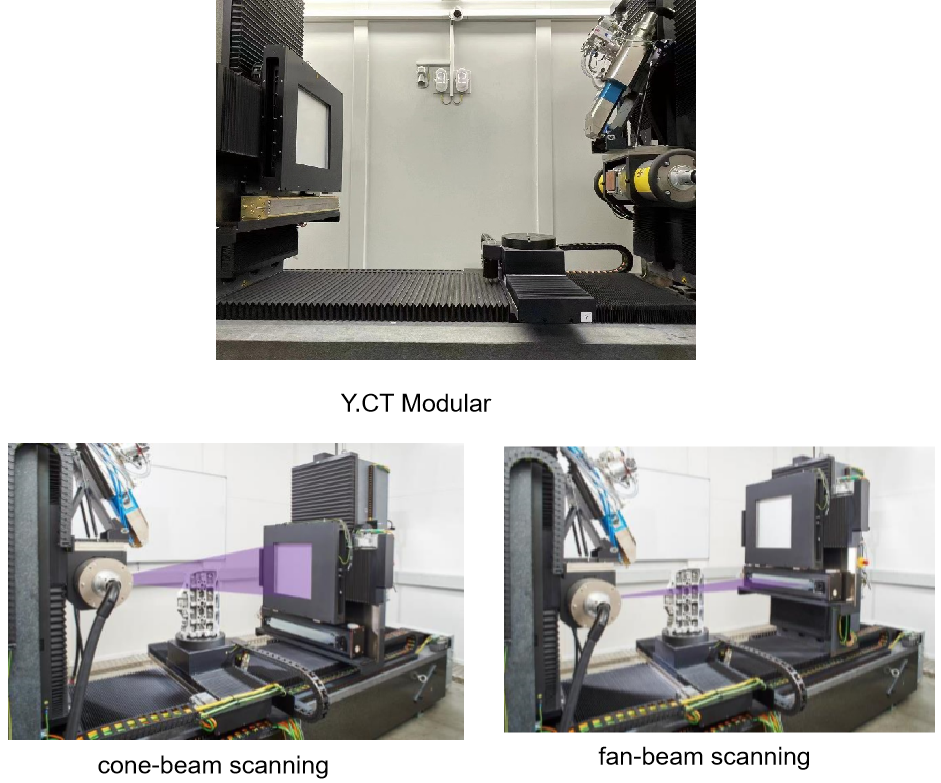

High-resolution computed tomography (German, YXLON, Y.CT Modular) system is a state-of-art machine with two X-ray tubes and two types of detectors.

The dual X-ray sources are a 450 kV with high penetration capability and a 225kV micro-focused tube with high resolution capability, and the dual detectors are a flat panel detector (2048 x 2048 pixels) and a line array detector (2356 pixels). In addition, the solid granite manipulator makes the system very precise, durable, warp-resistant and temperature-independent.

The system is the perfect combination of high precision and high energy, and combines cone-beam scanning and fan-beam scanning to achieve a perfect match of spatial and density resolution..

This system allows us to test an extraordinary spectrum ranging from measuring small electromechanical components to the analysis of large cast parts or even big cultural artifacts.

Equipment components

1. X-ray system components

|

Tube 1 |

Y.TU450-D11 |

Detector 1 |

Line Detector Array |

|

Maximum energy |

450 kV |

Active area |

598 mm (effective) |

|

Maximum power |

0.7 kW |

Pixel pitch |

254 μm |

|

Focal spot 450 kV |

0.4 mm / 1.0 mm |

Pixel matrix |

2,356 |

|

Tube 2 |

FXE 225.48 |

Detector 2 |

YXLON XRD 1620 |

|

Maximum energy |

225 kV |

Active area |

400 mm x 400 mm |

|

Maximum power |

~ 320 W |

Pixel pitch |

200 μm |

|

Focal spot |

≤ 3-220 μm) |

Active matrix |

2048 x 2048 |

2. Inspection item

|

Maximum part size (? x h) |

600 mm x 800 mm |

|

Turntable diameter |

300 mm |

|

Maximum part weight |

60 kg |

Focus-detector-distance (FDD):600-1750mm

|

Detector |

|

450 kV X-ray Tube |

225 kV Micro focus Tube |

|

Flat Panel |

Spatial resolution |

≤7LP/mm |

≤23LP/mm |

|

Contrast Sensitivity |

0.2% |

0.2% | |

|

LDA |

Spatial resolution |

≤6LP/mm |

≤18LP/mm |

|

Contrast Sensitivity |

0.15% |

0.15% | |

|

Maximum penetration depth(Fe) |

55mm |

20mm | |

4. Other equipment

(1) In-situ tensile test device

(2) In-situ fatigue test device