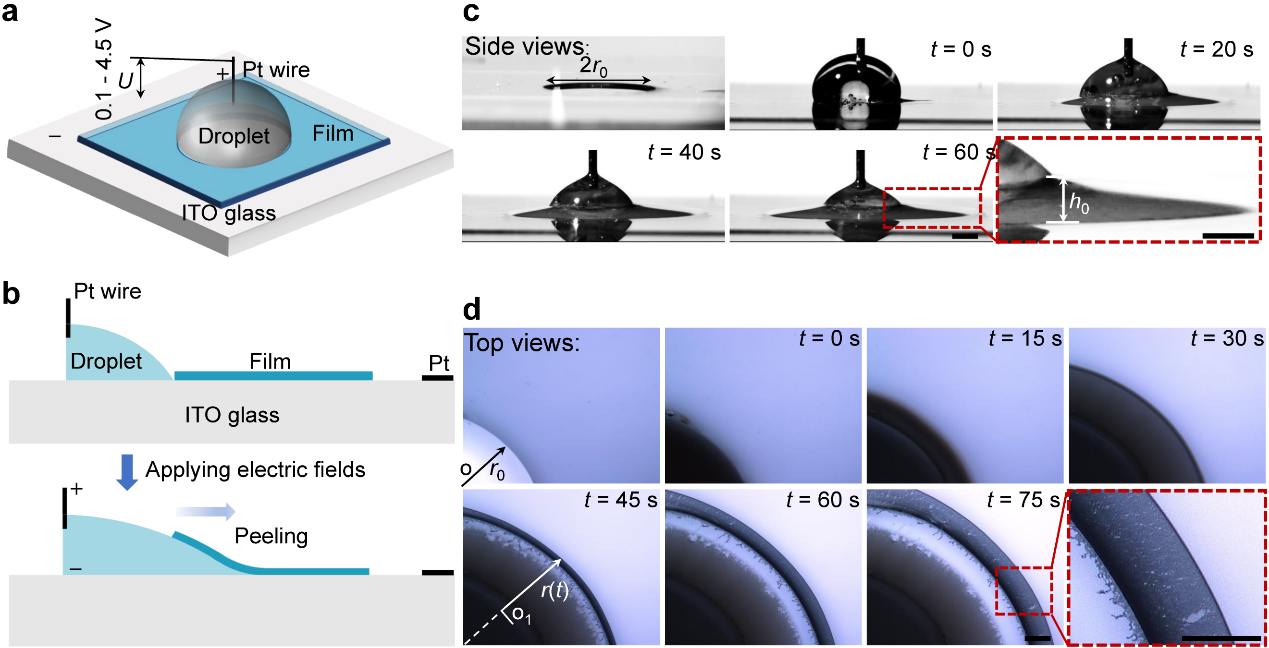

Figure 1. Experimental setup and characterization of electro-capillary peeling.

In this work, the author utilized a self-constructed mechano-electro coupling experimental platform to investigate the electro-capillary peeling of thin films. The results showed that the liquid droplet was driven to percolate and spread into the bonding layer for film detachment by applied electric fields (0.1-4.5 V). The electro-capillary peeling exhibits a symmetrical peeling process and remains relatively stable peeling rate under a constant electric field until achieving complete delamination of the thin film. The observation presented that a liquid droplet of 20 μL readily detaches a PDMS film with a radius of about 3 cm.

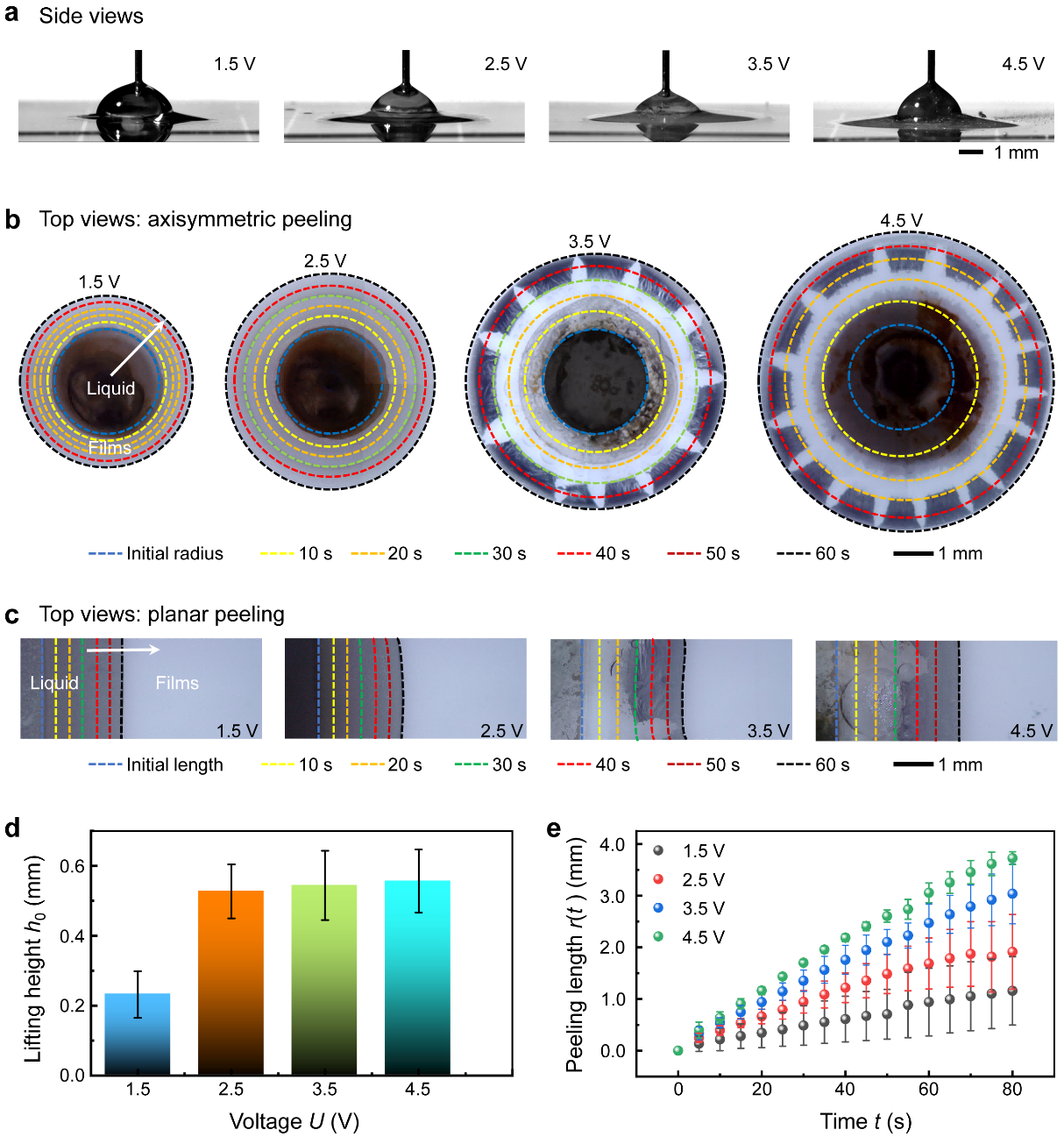

Figure 2. Electro-capillary peeling at different voltages.

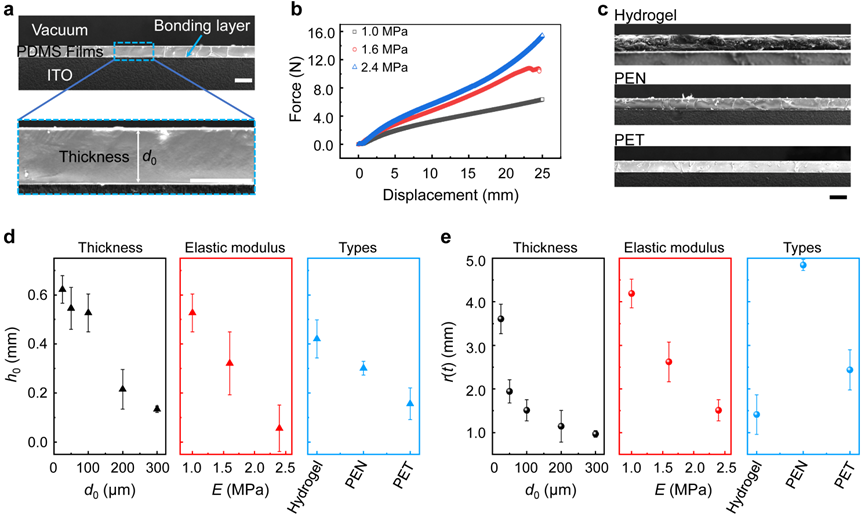

Figure 3. Electro-capillary peeling for various films.

To further explore the practicality of the electro-capillary peeling method, the author systematically studied the detachment process under different voltages, solutions, and thin film properties (thickness, elastic modulus, and types). As shown in Figures 2 and 3, the experimental observation presents that the electro-capillary peeling shows active control characterizations and is appropriate for a broad range of films (such as hydrogel, PDMS, PEN, and PET) and solutions (including acid, alkali, neutral aqueous solution, and organic solution). Although the performance of the electro-capillary peeling method was affected by the electric field, film, and solution properties, it was clearly appropriate for a broad range of applications.

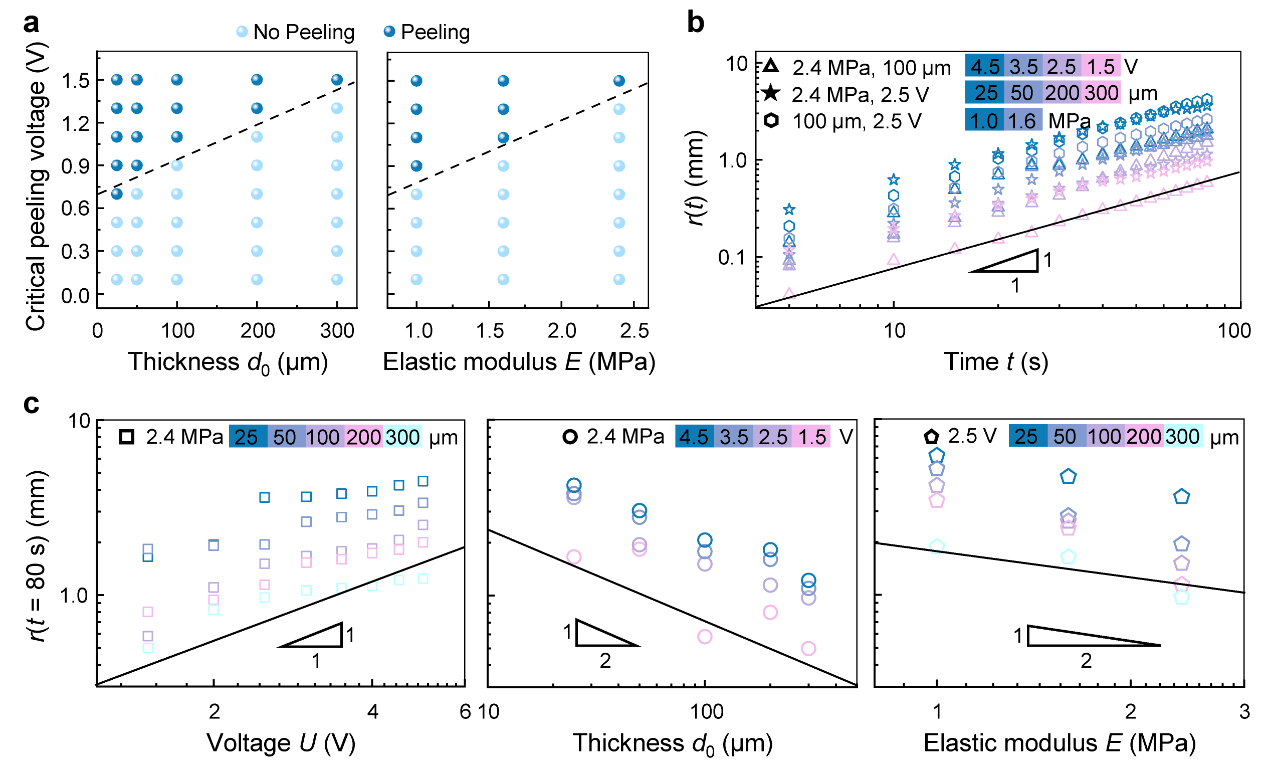

Figure 4. Working mechanism of electro-capillary peeling.

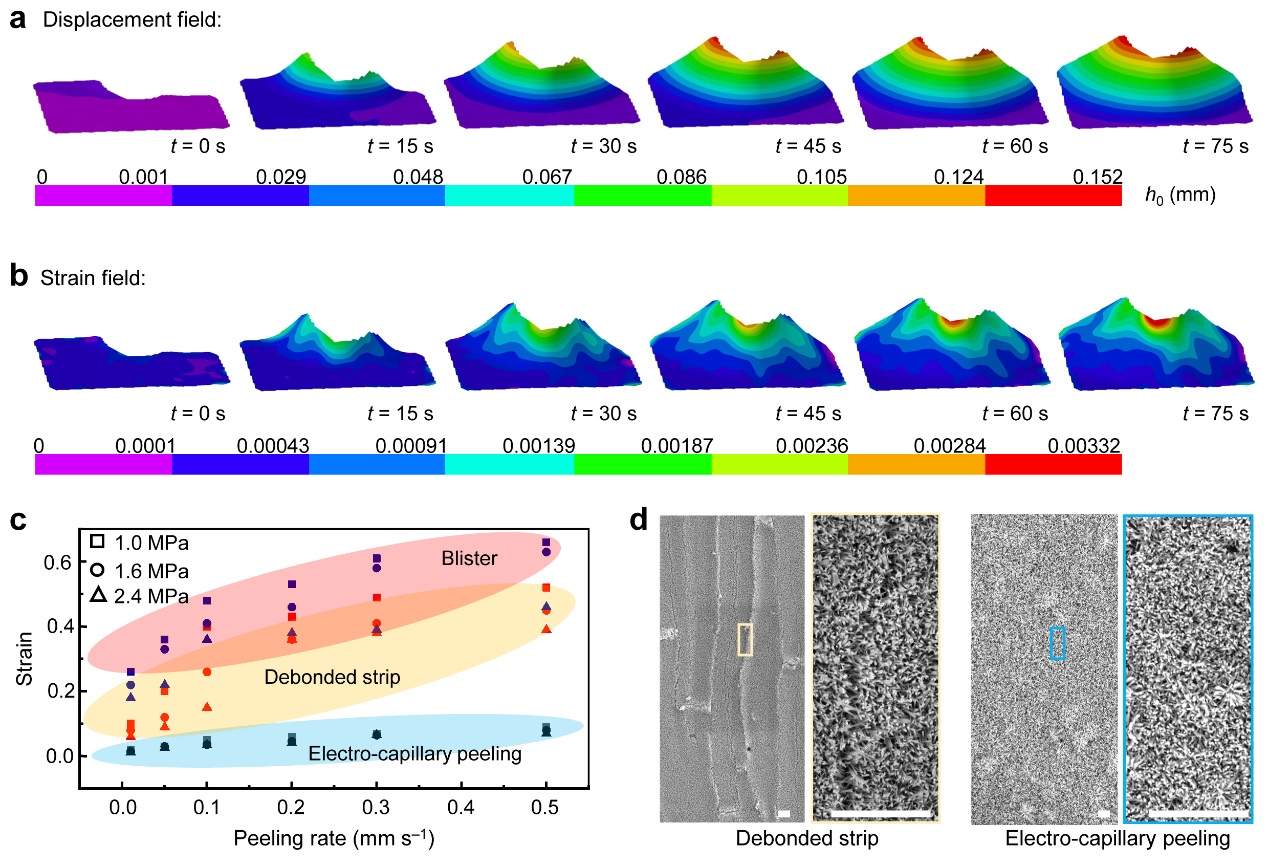

Figure 5. Deformation of the film during the electro-capillary peeling process.

In addition, the study established a theoretical model to analyze the electro-capillary peeling behavior under electric fields based on the theory of elasticity. Within the uncertainties, excellent agreement is shown between the predicted and experimental data (Figure 4). Finally, the deformation and strain field of the thin film shows that the film detached by the electro-capillary peeling method had a much smaller strain than that peeled by the traditional methods (with a strain of only 3.32‰). For this reason, the electro-capillary peeling method would be a valid approach to protect the functional device in these applications (Figure 5). With the wide use of micro/nanofilms, the new method of ‘‘electro-capillary peeling’’ should attract much interest from academics and industry and potentially facilitate ‘‘water-based peeling’’ utilized in practical applications.

This work is highly praised by the reviewers, who state that “the manuscript presented a new and interesting new direction in thin film processing. The science of the work is rigorous and thorough. I can also see direct and immediate societal impacts”. This work was jointly supported by the National Key Research and Development Program of China (Grant No. 2022YFA1203200) and the National Natural Science Foundation of China (Grant Nos. 12241205, 12032019).

Paper linkage: https://doi.org/10.1038/s41467-023-41922-2 (Li PL, Huang XF, Zhao Y-P. Electro-capillary peeling of thin films. Nature Communications, 2023, 14:6150.)