The strength and ductility are two critical properties of metallic materials. Strength ensures the reliability of the materials in serves, and ductility allows metallic materials to be formed into products with various shapes. A promising strategy involves microalloying with elements such as Ni, Co, Al, etc. to achieve improved strength through precipitation hardening. However, the precipitates endured rapid nucleation and abnormal growth due to thermally driven force during aging, which resulted in stress/strain concentration and catastrophic failure.

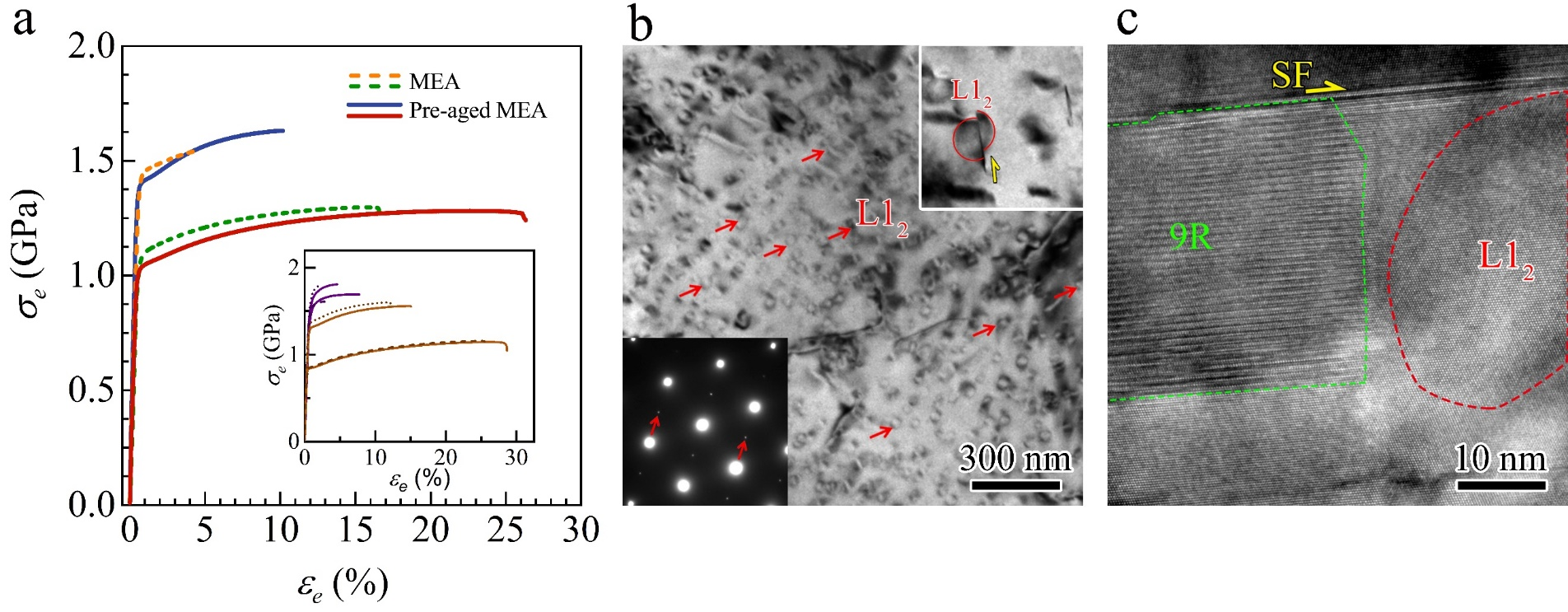

For this reason, the team obtains the randomly and uniformly distributed L12 nanoprecipitates (40 nm) by pre-aging, annealing, and post-aging in (CrCoNi)94Al4Ti2 medium-entropy alloy (MEA). Of great significance, the more randomly distributed L12 nanoprecipitates, along with heterogeneous grain structures, can result in a better tensile property. The pre-aging doubled the ductility without apparently sacrificing the strength. They found that, in pre-aged MEA, finely dispersed L12 nanoprecipitates with higher spatial density were sheared by dislocation, promoting planar slips, which favors geometrically necessary dislocations (GNDs) piling up to increased hetero-deformation-induced stress and strain-hardening. Stacking faults, Lomer-Cottrell locks, and 9R structures were formed in the MEA after deformation, which both could enhance the ductility of MEA.

This work was supported by the NSFC Basic Science Center Program for "Multiscale Problems in Nonlinear Mechanics", the National Key R&D Program of China, and the Hong Kong Research Grants Council.

The first author of the paper is Dr Zihan Zhang, and the corresponding authors are Dr Yan Ma and Professor Fuping Yuan, both from the Institute of Mechanics, Chinese Academy of Sciences. The collaborators include Professor Yuntian Zhu from the City University of Hong Kong.

Figure 1. (a) The stress-strain curves of pre-aged MEA and MEA. (b) High density of coherent nanoprecipitates and the dislocation shear the precipitate. (c) The interaction between Stacking faults, 9R structures, and precipitates.

More information: https://doi.org/10.1016/j.ijplas.2023.103821